COURSE DESCRIPTION

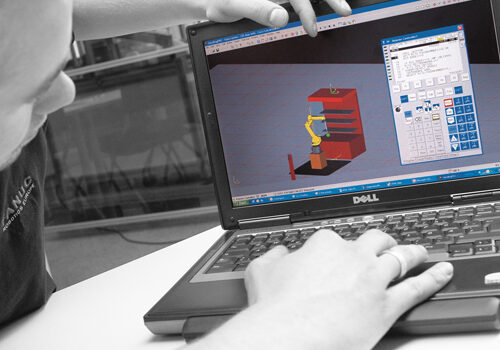

In this course, you will learn how to install and operate RoboGuide. How to create cells with fixtures and parts. How to create simple motion programs and create simulations. Upskill with FANUC Academy, and get the most from your robot and improve productivity.

COURSE OBJECTIVES

After completed course the participant should be able to:

Having RoboGuide installed on the participant’s computer.

Know how to manage the licenses for RoboGuide.

Know how to create a cell and what different options there are.

Importing and managing fixtures and parts.

Know how to move and position the robot.

Know how to create a simple program and use that to simulate the robot’s movements and how to record that simulation.

TOPICS

RoboGuide installation

RoboGuide Licensing Manager.

Cell Creation.

Fixtures and parts.

Virtual Jogging of the Robot.

Simulation Program Creation.

ADDITIONAL INFORMATION

4 people maximum (2 min.) online training.

Courses are presented in local language when appropriate (Swedish, Danish, Finnish) – otherwise courses are held in English. Course material is available in English.

Our Training Instructors have robot and RoboGuide experience.